SERVICES & ABILITIES

Services and Abilities

Our 70,000+ square-foot, craned manufacturing facility houses multiple pieces of equipment with a wide range of capabilities. Maintaining 500 tons of raw steel in inventory allows us to conveniently accommodate your specific needs in a timely manner.

We service a wide range of industries, including:

Department of Transportation

Municipal, State and Federal levels. (We are D.O.T. Approved in many U.S. states.)

Electric Utility

Renewable Energy

Steel Fabricators

General and Commercial Construction

Bending

We use both hot and cold bending methods in diameters ranging from ¾” -2-1/2”. Choose from a list of bending options including “L” Bends, “J” Bends, and U-Bolts. Specialty bends can be accommodated based on your engineering specifications.

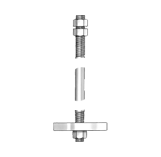

Anchor Bolt & Rebar Bolt Cage Assemblies

We bolt or weld your anchor bolt cage assemblies based on your specifications and the grade of steel. Many of our customers appreciate the convenience of having their cages delivered fully assembled and ready to use.

Cutting

We are able to saw cut or shear our bars. We prefer to saw cut all of our material in order to give our customers a clean, straight bar from end-to-end. Our multiple saw lines are capable of completing several jobs at once.

Threading (UNC)

We have threading machines capable of either cut or roll threading, allowing us to achieve a level of efficiency that allows us to meet our customers’ needs.

Swedging

Swedge bolts have indentations applied in specific patterns along the shaft of the bolt. These indentations must never be made by cutting into the steel but rather by “moving” or compressing the steel.

Rebar Cages

Rebar Cages are assembled according to your specifications and delivered complete and ready for installation.

Packing

We pack each job in such a way so as to secure the product during transit. Using steel banding, each order is safely stacked in a bundle or strapped to a wooden pallet. Smaller jobs can be placed in a box or wrapped in plastic-wrap. The ends of each bolt are color coded based on the grade of steel. If your project requires special bundling, handling or color coding please let us know.

Welding

FSA has welding capabilities for various foundations and structures. We routinely weld nuts or plates to anchor bolts, manufacture welded anchor bolt and rebar bolt cages as well as structural steel items and foundations, based on customer specifications.

Drilling & Tapping

The ability to drill and tap our own plates, plate-washers and other steel components allows us to reduce costs and improve our service to you.

Quality Control

Each process in our shop has a quality control check list that must be completed for each order. This means from start to finish a typical product will have been checked 3 or more times. There is a final inspection that comes after everything is packaged for shipment. These checklists and inspections are designed so that any discrepancy is corrected in-house, to ensure the product you receive is in compliance with your specifications

Protective Coatings

FSA has established strong relationships with various steel coating companies. These include, but are not limited to: Hot Dip Galvanizing, Zinc Plating and Powder Coating.

Logistics

Although FSA does not provide delivery service, we are happy to schedule the shipment and delivery of your order for you. We have established relationships with several leading freight companies and can have your order shipped just about anywhere. Freight quotes can be provided by request.